|

Model |

型号 |

SLT-SHA800 |

|

Width of roll material |

材料宽度 |

700mm |

|

Max. Diameter of roll material |

最大放卷直径 |

1000mm |

|

Max. Diameter of rewinding roll |

最大收卷直径 |

650mm |

|

Min. Width of slitting |

分切宽度 |

13.5mm,14mm,15mm |

|

Slitting Speed |

分切速度 |

0-300m/min |

|

Total Power |

总功率 |

15kw |

|

Overall dimension ( L x W x H mm) |

机器尺寸 |

22002100x1400 |

|

Weight |

重量 |

2600kg |

|

Mahchine Main Parts : 机器主要构成: |

|

The machine with unwinder , web guide , slitting system , rewinding unit ,transmission system ,electric control part , etc 本机由纠偏放卷机构、分切机构、收卷机构、传动机构以及电器控制等组成 |

|

Specification 各机构主要配置及规格 |

|

|

A.该机设有手动纵横向调偏,可消除原料两端因薄厚或纸芯不圆所致的张力不一及起皱。 |

B.采用高线性磁粉制动器作为放卷张力执行元件,输出扭矩均衡,可将张力波动降低到最低状态,通过西门子PLC自动在线检测计算材料卷经大小,自动控制放卷的张力输出。 |

C.上料方式:气动自动上卷(选配) |

D,气胀轴放料,100NM磁粉刹车控制张力,PLC控制自动张力输出。 |

|

E, Web Guide Control Ssyem E,纠偏控制进料 |

|

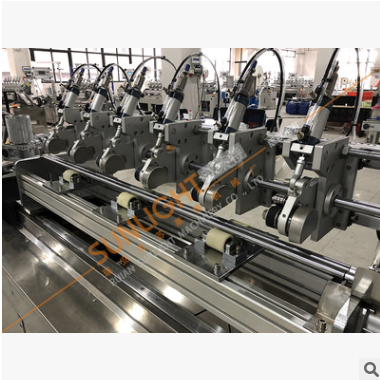

2,Slitting System 2,分切结构 |

|

The machine uses a round knife to cut, the incision is neat, and the service life is long. The upper and lower knife axes of the slitting are widened, and the speeds of the upper and lower knife shafts are matched by the gears. Rotate the hand wheel to implement the knife, and continue turning to achieve automatic knife. 该机构采用圆刀分切,切口齐整,寿命长,分切上下刀轴经过调宽处理,上下刀轴之间由齿轮进行速度匹配。旋转手轮实施下刀,继续转动可实现自动靠刀。 |

|

A, Slitting shaft , 1 set Top knife shaft and 1 set bottom knife shaft A, 刀轴:上、下刀轴 各1根 |

|

B, Locking device: With a rapid tool setting device, it can lock the upper knife shaft to avoid cutting quality problems caused by the upper and lower knife disengagement or movement. B,.锁紧装置:具有快速靠刀装置,能够锁紧上刀轴,避免上下刀脱离或移动而造成的分切质量问题。 |

|

C, High-pressure fan through the blowing pipe diversion, the waste edge come out C, 排废料:用高压风机通过吹料管导流,把废边料排除 |

|

D, 30MM Main wall plate: The use of steel wall panels, effective damping, to facilitate the smooth operation of the machine at high speed D, 30MM 主墙板:使用钢板墙板,有效减震,有利机器高速平稳作业 |

|

E, φ100×950mm Guide roller: chrome plated, polished E, φ100×950mm导向辊:表面镀铬,抛光处理。 |

|

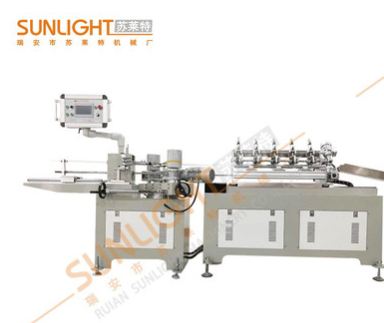

3, Rewinding Unit 3,收卷部分 |

|

A, This machine adopts two-axis rolling of the left and right axles. It is equipped with a pressure arm to balance the pressure inside and outside the winding. The drive adopts two frequency conversion vector motors, the uniaxial tension is arbitrarily adjustable, and the winding tension increases with the increase of the winding volume. The winding volume is automatically calculated by the PLC and the control tension is automatically calculated. A, 该机采用左右轴双轴收卷,设有压臂平衡收卷内外压力。传动采用两台变频矢量电机,单轴张力任意可调,收卷张力随着卷经的增大而增加,通过PLC自动计算卷经,自动计算控制张力。 |

|

B, Servo Motor control rewinding,steel shaft rewinding,and paper core PLC control tension。 B,伺服电机控制收卷,气胀轴轴收卷,纸管支撑。PLC控制收卷张力 |

|

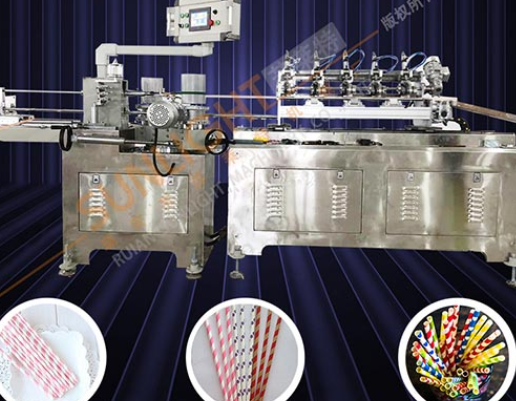

4, Driving unit 4, 传动部分 |

|

A, The inverter is used to control the 5.5KW main motor operation, the speed of the lift is convenient and fast, and the speed adjustment is excessively soft and steady. A, 采用变频器控制5.5KW主电机运转,升降速方便快捷,速度调节过度柔和、平稳。 |

|

5, Main Electrical Part 5, 主要电器 |

|

A, Centralized control of the cabinet, beautiful and easy to operate. PLC automatic tension control A, 集中电柜箱控制,美观大方,操作方便。PLC全自动张力控制 |

|

B, One meter counter , real-time linear speed real-time, meter meter auto stop function (with deceleration stop function, remember meter basically no error) B, 计长显示器1件,实时线速度现实,记米自动停止功能(带减速停止功能,记米基本无误差) |

|

C, 按钮、接触器、空气开关等 C, Button,Contactor,air switchair |